Paul Barton

Supplier-

Posts

49 -

Joined

-

Last visited

Reputation

0 NeutralAbout Paul Barton

Personal Information

-

First Name

Paul

-

Last Name

Barton

-

Location

Swindon

Recent Profile Visitors

2,527 profile views

-

The 2.85mm filament is rarely used in the sort of machines most people use. I only use polymax pla tough filament as it's performance is so much better than anything else. Sorry can't be of more help The printer looks a mean beast but the results are what matter.

-

Officially you need to apply to the IOM registrar for a hull number probably in the 5000+ range. Then you could use the last 2 digits of the new number. Alternatively you could apply for a personal number for a small fee. If 20 is available all good. If you don't sail outside your local club you could just put 620 on your sails. Please post some pictures.

-

Paul Barton started following Alioth V3 - Now available

-

Really good idea.

-

I have printed approx. 20 hulls for customers and there are close to another 20 self printed.

-

Hi Steve, I originally found them on Etsy but more recently got them from Aliexpress. They are 100mm can lids. There are a few inserts that have been designed to use the clip on lid. paul

-

There is hardware parts list in the files section https://www.facebook.com/groups/373682077022782/files/files Sails etc also have a list - just ask for the Alioth parts list Warm regards Paul

-

Hi Stephen B, The hull kit is £330. The fin, rudder and ballast £358 - allow £150 per rig set, sail winch £250 (RMG), Rudder servo £35, TX/RX and battery £100. Add around £100 for hardware etc. Total around £1473. I rarely offer complete hulls as I'm so busy printing the Kits. Call me on 07966490048 Warm regards Paul Barton

-

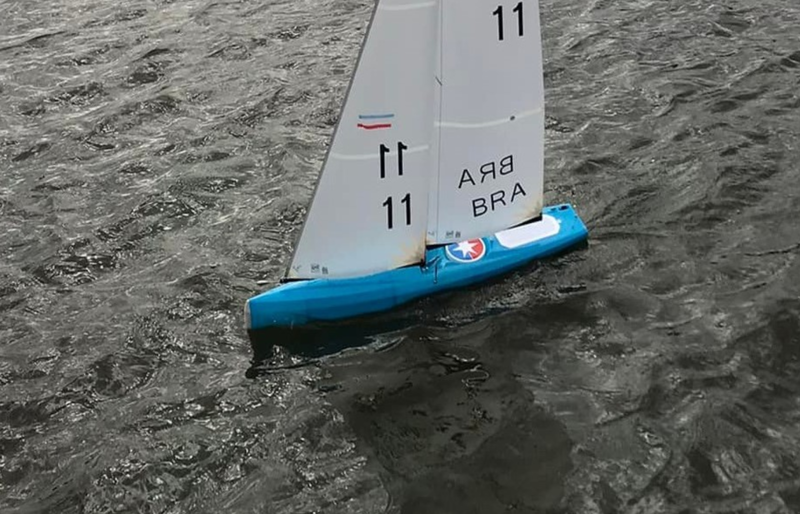

The Success of the Alioth is noteworthy. matches the performance of the best designs currently available the way its printed means that it needs very little if any surface finishing the strength of Polymax PLA tough means that it really is stronger than GRP can now be assembled in a few hours The Alioth V3 is now available in 3 hull sections. Clip on pot lid, bow bumper supplied in white. Fittings kits available form Sails Etc. Colours available are: Teal (turquoise) yellow (slightly translucent) Orange (slightly translucent) White Red Grey Or a combination of the above in any way you choose. Prices for a hull kit (you add fin,rudder, ballast servos etc) is £330 plus £15 shipping. Delivery is normally a week. Confirm your order on a Monday and get your kit on Friday and be on the water the following Monday!

-

We are delighted to partner with Juan M Egea who has designed an outstanding competitive IOM. The boat can be printed from digital files relatively easily and there are now several licensed builders around the world who will print a hull Kit for you to an accepted standard. These hulls are very easy to assemble, because of the way they are printed, and equally easy to finish because of the outstanding surface finish. Most will simply need a light spray with a clear coat polyurethane finish. For more information go to the Alioth Facebook Group. There is further information at the Alioth IOM site.

-

Paul Barton started following 3D Printed RC Yachts

-

Hi I'm just starting out on this quest. We have a club member who is quite disabled physically. He currently sails a Hansa at international level and wants to try his hand at RC sailing. Has anyone modified a Tx for very limited range of movement. We're not talking about putting all controls onto one stick here. He sails his hansa by a sequence of pushes on buttons with the back of his hand (i think). I'm going to approach the people who make the control system for the hansa as well. Warm regards Paul

-

Thanks darin Warm regards Paul

-

I'm trying to find out what level of insurance cover MYA affiliation provides. The policy talks about £5 million but I'm just after clarification Warm regards Paul barton

-

Thanks Chris your suggestion is very helpful

-

We have a really good problem at the www.CotswoldModelYachtclub.co.uk because we've seen very significant growth in the last year and we now face the problem of having a fleet where we have 15 boats on the startline. If we get much bigger we will be knocking on 18-20 in a few months. My question is how should we best manage the fleet. It's a bi weekly fleet of 'small boats' comprising 10+ DF65 with a few affinity and one 3d printed RG65. I've looked at HMS but it seems too complicated and doesn't seem to work for a series where people drop in and drop out. We've heard of people splitting the fleet into A and B fleets and promoting boats from one fleet to another at the end of the year or even monthly. So open to ideas please.

-

Repaired winch on its way back. Motor and pot replaced. Old switch is toast so new one on order. Progress is being made. Just need to check hull thoroughly for historical hairline cracks. Any ideas how to find them. Wondered about using a dye? Paul